Amalgamating tape, also known as self-fusing or self-amalgamating tape, is a versatile and handy tool to have in your toolbox. This type of tape is used to create a water-tight seal around a variety of surfaces. It is commonly used in plumbing, automotive, and electrical applications.

In the realm of automotive manufacturing, the use of high-quality fabric tapes has become increasingly prevalent. These tapes, often made from a blend of synthetic and natural fibers, offer a range of benefits that make them an indispensable tool for various automotive applications. There are several types of blue tape electrical available on the market, each with its own unique properties and applications. Some of the most common types include In addition to durability, factory floor tape offers flexibility in application. With a wide range of colors, widths, and patterns available, it is easy to customize floor markings to suit specific needs and requirements. Whether it's creating a designated area for equipment storage or marking off restricted zones for safety reasons, factory floor tape provides a quick and efficient way to establish clear boundaries within the workplace. Furthermore, the adhesive backing of the tape makes it simple to install and remove, allowing for swift and hassle-free reconfiguration of floor layouts as needed

factory floor tape.

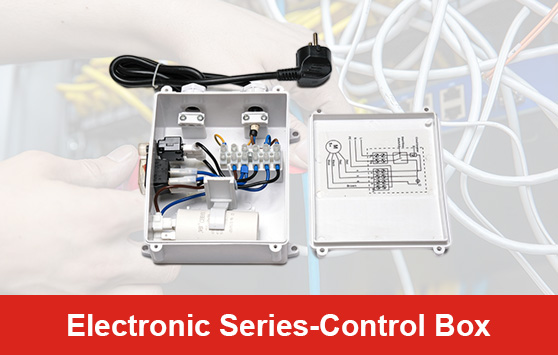

Control boxes are primarily employed to regulate electricity flow in electrical components. This means they playan essential role in safeguarding your devices. They are however multipurpose interfaces capable of fulfilling numerous roles.

This sealing tape fuses to itself instantly and is very long lasting.

Properties of Butyl Rubber

The selection of the right type of expansion joint foam strip is crucial Another important use of tape in construction is for securing cables and wires. By using specially designed electrical tape, construction workers can safely bundle and insulate wires, reducing the risk of electrical hazards. Additionally, duct tape is often used to temporarily secure cables to walls or floors, providing a quick and easy solution for keeping them out of the way during construction. Butyl rubber tape manufacturers have perfected the science behind this remarkable product, blending innovation with traditional manufacturing techniques. The butyl rubber itself is a copolymer of isobutylene and isoprene, offering exceptional impermeability to gases and excellent resistance to moisture, extreme temperatures, ozone, and UV radiation. This chemical composition makes butyl rubber tape an ideal choice for applications requiring long-term reliability without degradation. 3. Grounding In some cases, wire wrap tape can be used as a grounding conductor, providing a low-resistance path for electrical current to flow.

Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl

Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl Most tapes come with an adhesive backing that adheres firmly to most surfaces, including concrete, wood, and vinyl

Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance

Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance

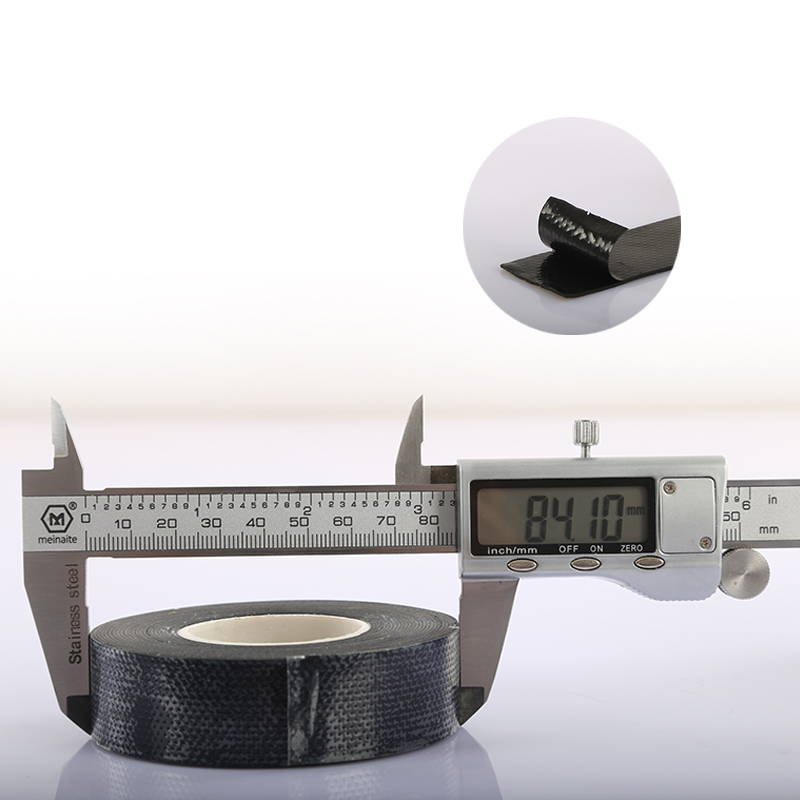

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions. 4. Fiberglass Tape Fiberglass tape is an insulating tape that is made from woven glass fibers coated with a heat-resistant resin. It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions. 4. Fiberglass Tape Fiberglass tape is an insulating tape that is made from woven glass fibers coated with a heat-resistant resin. It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications

It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications It is highly durable and can withstand high temperatures, making it suitable for use in high-voltage and high-temperature applications